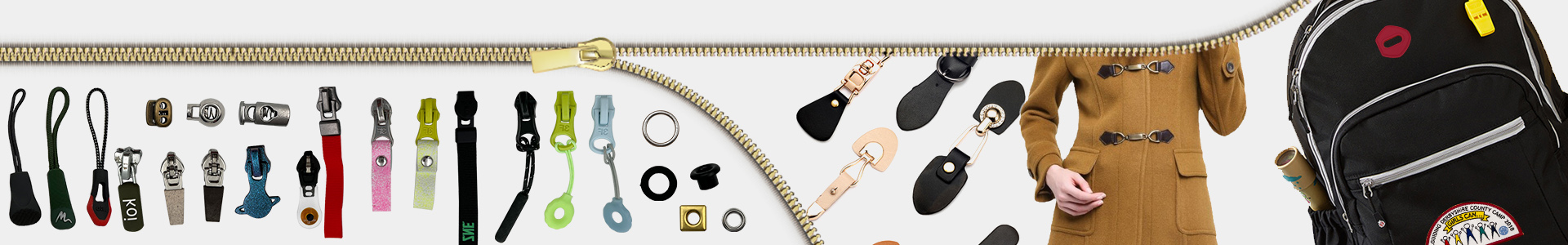

1. Raw Material Selection

The journey begins with the selection of raw materials. Liquid Silicone Rubber (LSR)is a common choice for injection molding due to its excellent properties, including high-temperature resistance (typically from -60°C to +250°C), flexibility, biocompatibility, and excellent resistance to chemicals and weathering. LSR is typically supplied as a two-part system (Part A and Part B) that must be mixed in a precise ratio before the molding process begins. This precise formulation is critical to achieving the desired hardness, color, and mechanical properties of the final puller tab.

2. Mold Design and Fabrication

The mold is a fundamental element that defines the shape, dimensions, and surface texture of the zipper pull tab. The design process typically involves Computer-Aided Design (CAD) software to create a precise 3D model of the mold . Key considerations in mold design include:

• Cavities: The number of cavities in the mold determines how many pull tabs are produced in a single cycle, crucial for high-volume production .

• Gates and Runners: These are channels that guide the liquid silicone into the mold cavities. Proper design is essential to ensure the material fills the cavity completely without defects .

• Cooling Channels: A network of channels circulates coolant to manage the mold's temperature, which is vital for consistent curing and cycle times .

Once the design is finalized, the mold is fabricated, often from hardened steel or aluminum, using high-precision techniques like CNC machining or electrical discharge machining (EDM) to ensure accuracy and durability .

3. The Silicone Injection Molding Process

With the mold ready and materials prepared, the core injection molding process begins. This is a cyclic automated process consisting of four key stages :

3.1 Clamping

The two halves of the mold are securely closed and held together under high pressure by a clamping unit. This ensures the mold is tightly sealed to prevent any silicone leakage during injection .

3.2 Injection

The two-part LSR mixture is fed into the injection molding machine, where it is heated and mechanically mixed. The resulting liquid is then injected into the closed mold under high pressure. The goal is to fill 95-99% of the mold cavity, ensuring the material reaches every intricate detail of the pull tab's design .

3.3 Cooling

After the mold cavity is filled, the silicone is allowed to cool and cure. The cooling stage, which can account for 70-80% of the total cycle time, is critical for the part to solidify and maintain its shape. The mold's temperature is carefully controlled through cooling channels to ensure uniform curing and optimal efficiency .

3.4 Ejection

Once the silicone has cured, the mold opens. Unlike traditional thermoplastics, LSR parts often do not require ejector pins due to their flexibility; they are designed to be easily released by the mold's opening mechanism. The finished pull tab is then ejected from the mold .

4. Post-Molding Operations

Once the basic pull tab is formed, it often undergoes several post-processing steps to meet quality standards :

• Deflashing: Excess thin material (flash) that seeped out of the mold seams is meticulously removed. This can be done manually or through cryogenic deflashing.

• Trimming: The sprue (the channel through which the silicone entered the cavity) and any other excess material are trimmed away to achieve the final shape.

• Curing: Some silicone products may undergo a secondary curing process in an oven to enhance their physical properties.

5. Quality Control and Inspection

Quality control is integral to the entire process. After ejection and post-molding, each silicone pull tab undergoes rigorous inspection . This includes:

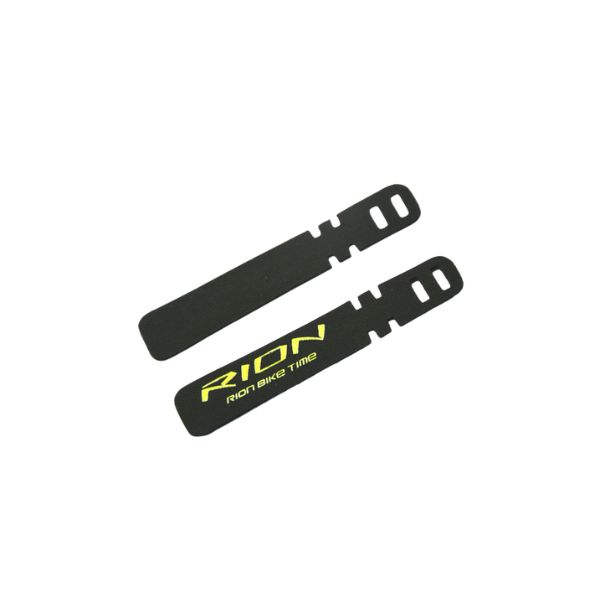

• Dimensional Checks: Verifying that the part's dimensions match the design specifications.

• Visual Inspection: Checking for surface defects like bubbles, discoloration, or incomplete filling .

• Functional Testing: Ensuring the tab's clasp or attachment mechanism works correctly.

Advanced manufacturers may also perform tests for hardness, tensile strength, and material safety to ensure the product's reliability and compliance with industry standards .

📧Email ua at info@jing-tex.com for more details.