The Lie Behind the Label

A factory manager will meet your eyes, smile, and swear they're using the premium alloy you paid for. Meanwhile, their buyer is haggling in a back alley for "grade-B" scrap metal—saving three cents per piece, but risking everything your brand stands for.

You won't notice it at first. Not when the order ships. Not when the line sheet looks perfect. But your customer will.

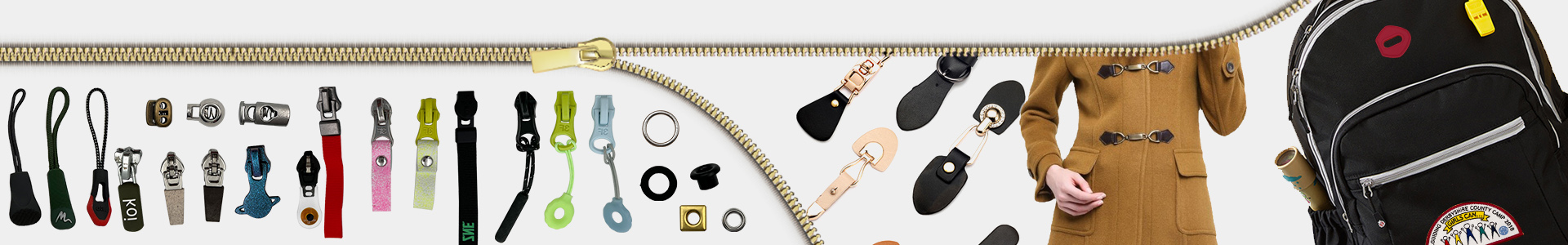

They'll feel it when the zipper jams mid-stride on a $500 trench coat. Hear it when the "custom"button snaps under the strain of a heavy-duty backpack. Sense it when the once-buttery-soft trim now feels rough, like sandpaper against their neck. That "crunchy"sound? That's not just a faulty part. It's your brand's reputation cracking.

Why "Cheap Swaps" Are a Death Sentence for Luxury & Performance Brands

For luxury labels, trust is currency. A single faulty zipper can turn a loyal client into a vocal detractor on social media. For performance brands, reliability is non-negotiable—an outdoor jacket with a weak snap fails when it matters most, eroding faith in your "extreme conditions" promise.

Here's the truth: Most "identical" hardware isn't identical at all. The difference lies in what you can't see:

Alloy Purity: Grade-A zinc alloy vs. recycled scrap with lead contaminants (and no OEKO-TEX certification).

Precision Engineering: Custom-molded dies that eliminate burrs vs. hand-stamped parts that snag fabric.

Durability Testing: 10,000-cycle zipper pulls vs. 1,000-cycle "good enough" alternatives.

These aren't minor details. They're the line between "investment piece" and "disposable junk."

Our Hardware: A Quality Firewall for Your Brand

At JINGTEX, we don't make "hardware." We make brand armor.

Our trims are engineered to be impossible to fake. Here's how:

Custom Alloys: We source conflict-free, eco-certified metals (yes, we'll show you the certificates) and blend them in-house for consistency—no off-the-shelf shortcuts.

Precision Molding: Every die is CNC-machined to micron-level accuracy, ensuring every zipper tooth, button shank, and rivet fits perfectly. No burrs. No weak points.

Rigorous QA: From salt-spray corrosion tests to tensile strength checks, we reject any part that doesn't meet yourstandards—even if it passes "industry average."

When you use our hardware, you're not just buying a component. You're buying an insurance policy against "The Cheap Swap."

How We Turn Crisis into Trust

We didn't start by chasing new clients. We started by fixing their messes.

Last year, a luxury outerwear brand came to us after a wave of returns: Their $800 parkas were being returned because the "premium" buttons kept breaking. The original supplier had swapped their custom alloy for a cheaper alternative—without telling anyone.

We reverse-engineered the failure, recreated the exact alloy they'd paid for, and added a 20% safety margin to the tensile strength. Today, that brand uses our buttons exclusively. And their return rate? Down 92%.

That's who we serve: Brands that refuse to let cost-cutting kill their reputation.

Luxury isn't about price tags. It's about consistency. Performance isn't about marketing claims. It's about reliability.

Your customers don't just buy your product—they buy the feeling of owning something that lasts. Don't let a "cheap swap" steal that feeling.

Let's build something that endures.

[Contact Us] to request a sample of our un-fakeable hardware—and hear the difference silence makes.