For manufacturers of outdoor gear and workwear, functional trims are as crucial as the main fabric. However, these components often face unique challenges that can compromise a garment's integrity. Understanding these issues is key to delivering reliable products.

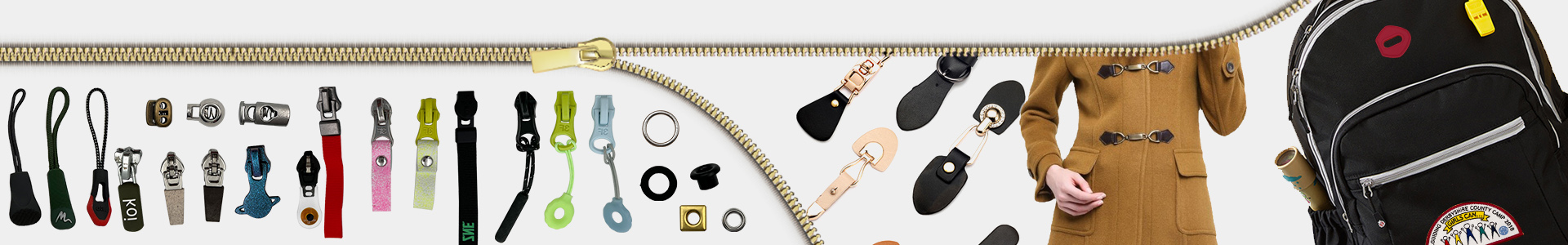

1. Zipper Failure

A common point of failure is the zipper. Problems range from sliders jamming on coil zippers to teeth separating under stress. In waterproof garments, a standard zipper becomes a major leak point.

Solutions: Specify self-healing coil zippers for smoother operation. For high-stress areas like pockets and cuffs, two-way auto-lock sliders prevent accidental opening. For waterproofness, laminated waterproof zippers or zipper garages are essential to seal out the elements.

2. Hook-and-Loop (Velcro) Degradation

Hook-and-loop closures lose grip over time. Lint, thread, and debris clog the hooks, while the loop side can wear down from abrasion, rendering the closure useless.

Solutions: Use anti-fouling hook options designed to resist debris buildup. For the loop side, select high-density, abrasion-resistant polyester loops. Matching the strength of the hook-and-loop to the garment's specific use case prevents over-engineering and premature wear.

3. Button and Snap Detachment

Buttons and snaps are subjected to constant pull and torque. Standard attachments can fail, leading to lost components. Metal snaps can also feel uncomfortably cold in freezing outdoor conditions.

Solutions: Reinforce attachments with bartacking at the stitch. For cold environments, polyamide (plastic) snaps are a superior choice as they do not conduct cold like metal. Always ensure the base material of the snap is corrosion-resistant.

4. Elastic and Drawcord Failure

Elastics in cuffs and waistbands can lose their recovery after repeated exposure to moisture, UV rays, and harsh detergents. Drawcords can shrink or become stiff, making them difficult to adjust.

Solutions: Opt for heat-resistant and silicone-impregnated elastics that maintain elasticity. For drawcords, specify 100% polyester cord (which has minimal shrinkage) with a smooth, low-friction coating to ensure easy glide through cord locks.

By proactively selecting the right trims designed for the rigors of the environment, brands can significantly enhance the durability, functionality, and lifespan of their apparel, reducing returns and building consumer trust.