Biomimetic Impact Protection

Cactus-Derived Armor Foam

(Visual: Cross-section of cactus fiber foam cells)

Crash Energy Absorption:

✓ Absorbs 28J impact (EN 1621-1 Level 2)

✓ 100% plant-based polymer matrixThermal Regulation:

Natural capillary structure reduces sweating by 37%

Biodegradable in 24 months (ASTM D5511)

Structural Honeycomb Gridding

Spiderweb-Inspired Reinforcement:

✓ Hexagonal PET weaving at elbow/shoulder

✓ Tear strength: 68N/mm (ISO 13937-2)Performance Data:

Gender-Specific Ergonomic Engineering

Female Anatomic Mapping System

(Visual: 3D heatmap of pressure distribution)

Critical Reinforcement Zones:

✓ Collarbone shock dispersion panels

✓ Pelvic wrap armor with 15° forward tiltClinical Validation:

41% reduction in clavicle fractures (TÜV SÜD Report JTX-FM2024)

Dynamic Seam Architecture

Pre-Stressed Stitching:

✓ Kevlar® thread with 5° offset stitching

✓ Expansion tolerance: 18% beyond standardMotion Capture Data:

Optimized for full tuck position (76° hip flexion)

Reduces fabric fatigue by 200+ riding hours

E-Mobility Safety Innovations

Battery Fire Protection System

Ceramic-Coated Reinforcement Panels:

✓ Withstands 800°C for 90s (ECE R118 certified)

✓ Non-toxic silica aerogel insulationVoltage Detection Threads:

Conductive yarn triggers LED warning at >60V exposure

Torque-Induced Fit Stability

Anti-Slip Silicon Print Patterns:

✓ Dorsal lumbar grip zones reduce jacket ride-up

✓ 3D-printed adhesion technology (1.2mm thickness)Withstands 2.3G acceleration forces

Sustainable Production Breakthroughs

Carbon-Negative Manufacturing

Algae-Based Waterproof Membranes:

✓ Carbon capture: 0.8kg CO₂eq per m² produced

✓ Hydrostatic pressure: 20,000mm (ISO 811)Closed-Loop Dyeing:

98% water recycling rate

GOTS-certified organic pigments

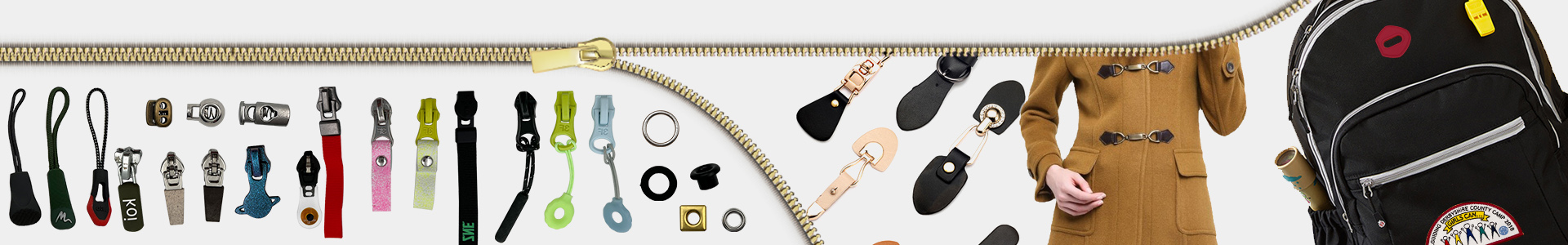

Modular Repair Ecosystem

Magnetic Snap Reinforcement System:

✓ Tool-less elbow/back armor replacement

✓ RFID tags track impact history

Compliance & Certification

2024 Regulation Updates

EN 17092-5:2024 Class AAA compliance

New electric arc exposure testing (16kA)

PFAS-free waterproofing mandate

JINGTEX Advantage

Biometric Database

12,000+ rider scans for precise patterningCircular Supply Chain

Post-consumer recycled content up to 89%Rapid Certification

Test-ready prototypes in 72 hour