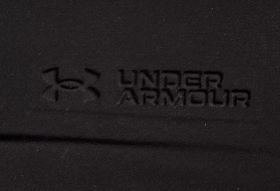

The appeal of relief embossed and debossed finishes lies in their unique set of characteristics that elevate a garment's feel and appearance.

• Premium and Tactile Experience: Relief embossing or debossing's primary advantage is the three-dimensional texture it creates. This tactile quality invites touch, significantly enhancing the perceived value and luxury of the garment . Debossing provides a sophisticated, multi-sensory experience that flat printing methods cannot match.

• Visually Striking Through Dimension: Relief embossing techniques use light and shadow to create depth, making designs stand out with a subtle elegance . Embossing, with its raised effect, is particularly effective at catching light, while debossing creates a refined, sunken impression .

• Durability and Ink-Free Decoration: Since the design is physically pressed into the fabric fibers rather than printed on with ink, it is highly durable. The finish is long-lasting and won't crack, peel, or fade like some traditional prints can . This also makes it an elegant, ink-free decoration option .

• Subtle and Versatile Branding: Debossing, in particular, offers an understated and modern aesthetic that is ideal for minimalist branding . Both techniques can be combined with other methods, such as foil stamping, to add color and metallic shine, further expanding their creative potential .

Ideal Fabric Qualities and Types

The success of embossing and debossing heavily depends on the fabric's properties. Not all materials are equally suited for these techniques .

The most important factor is the fabric's weight and thickness. Heavyweight materials with a firm, dense structure are ideal because they can hold the three-dimensional impression effectively . Generally, fabrics weighing over 200 grams per square meter (gsm), such as thick cotton sweatshirts, hoodies, and French terry, yield the best results . These fabrics provide enough substance for the press to mold a crisp and lasting impression.

Key qualities to look for include:

• Firmness and Stability: Fabrics with minimal stretch are preferred, as they are less likely to distort the impression over time or during the process .

• Smooth Surface: A relatively smooth surface, like that on high-quality cotton or leather, allows for a cleaner and more defined impression compared to highly textured fabrics .

The following table summarizes fabrics that are well-suited and less-suited for Relief embossing and debossing .

Highly Suitable Fabrics Less Suitable Fabrics

Heavyweight Cotton (e.g., for sweatshirts, hoodies) Lightweight Cotton (e.g., thin t-shirts)

French Terry Blouses with loose weaves

Fleece Stretchy Jersey Knits

Denim Silk

Leather & Faux Leather Lightweight Synthetic Blends

Canvas

To help you decide, here is a concise summary of the key points.

Relief embossing and debossing Advantages:

• Creates a high-end, luxurious feel and appearance .

• Offers excellent durability as the design is physically molded into the fabric .

• Provides a unique, ink-free alternative for subtle and sophisticated branding .

Relief embossing and debossing Limitations:

• Not suitable for lightweight or stretchy fabrics .

• Works best with bold, simple designs; fine details may not be captured clearly .

• Involves an initial cost for creating the custom molds (dies), making it less cost-effective for very small quantity orders.

Contact us by email info@jing-tex.com or phone +86 13790341692 for more detailed information.